Xiaomi’s new car production method is quite similar to Tesla’s Gigacasting, helping to significantly reduce costs and production time, which will greatly affect the selling price of Xiaomi electric cars in the future.

Main content Hide / Show What’s special about Xiaomi’s new car production method?

Just a few days after it was reported that Tesla abandoned its ambitious plan to mold the entire car chassis into a single block, Xiaomi revealed the innovations they are applying in their production process.

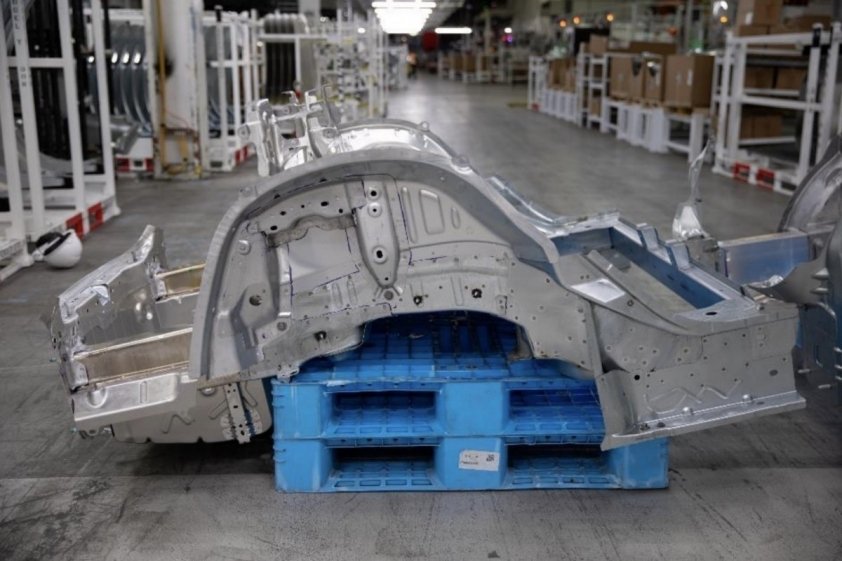

The frame of the vehicle can be made in 1 casting

Xiaomi claims to be the only Chinese automaker at the present time using two self-developed technologies including die-casting alloys and large die-casting equipment cluster systems.

Tesla was a pioneer in the use of large die casting, which helped replace many individual components into a single large part.

Some other Chinese manufacturers such as XPeng and Nio have also started using die casting technology.

Xiaomi’s system was developed in-house with Haitian cooperation.

Xiaomi 9100t production line

This machine produces the rear deck part of the Xiaomi SU7 and reduces from 72 parts requiring stamping and welding to a single molded part, which can be produced in 100 seconds.

In addition, it also increases the life of the integrated floor control panel, which can easily achieve a mileage of more than 2 million kilometers, which is more than 10 times the life of the traditional floor control panel.

A major criticism of this type of manufacturing is the cost of replacing parts if damaged.

Xiaomi has developed a whole molding machine system including 60 devices and 433 processes, of which the Xiaomi 9100T Super Molding machine is just one of them.

The Xiaomi car factory is highly automated and when it reaches maximum capacity, it will be able to produce 40 cars per hour, or one car every 76 seconds.