Turbocharger, or Turbocharger is a device operated by the engine’s exhaust flow, helping to increase engine power without having to increase cylinder capacity.

A turbocharger, also known as a Turbocharger, is a forced induction device, attached to the engine’s exhaust manifold.

Turbo engine

More specifically, Turbo is a device that helps stuff compressed air into the engine, creating a pressure increase of 1.4 to 1.5 times, causing fuel to burn in a shorter period of time.

Regarding fuel consumption, for example with a 1.6 Turbo engine, we will have the same capacity or more than a regular 2.4L engine, but the gasoline consumption will only be equal to a 2.0L engine.

| Turbo engine structure | |||

| No | Part | Describe | Function |

| first | Turbo shaft | The part that connects the air compressor impeller and the turbine impeller (the impeller that catches the engine exhaust stream). | Transfers kinetic energy from the turbine fan to the air compressor fan. |

| 2 | Turbine blades | The impeller is attached directly to the Turbo shaft, located inside the air compressor housing. | Receives the exhaust flow from the engine, rotating the Turbo shaft, thereby moving the air compression fan. |

| 3 | Air compressor impeller | A part mounted on the other end of the Turbo shaft, located inside the air intake housing. | The air compressor fan moves at high speed, sucks in clean air and compresses it at high pressure, bringing it inside the combustion chamber. |

| 4 | Air intake cover | It is a part with a spiral design, surrounding the air compressor fan. | Helps create and direct the path of compressed air flow. |

| 5 | Air compressor housing | Is a spiral-shaped part that covers the turbine fan, with the exhaust facing outward. | Has the effect of receiving exhaust airflow from the engine, driving it to rotate the fan blade and send the exhaust airflow outside. |

| 6 | Bearing support | The part is designed at both ends of the Turbo shaft. | They are both a part that supports and fixes the motor shaft, and a part that helps reduce friction and increase the rotation speed of the fan and shaft. |

| 7 | Cooling unit | Is the part directly connected to Turbo. | Using an air cooling system, reduces the temperature of compressed air before entering the combustion chamber. |

Turbo engine structure

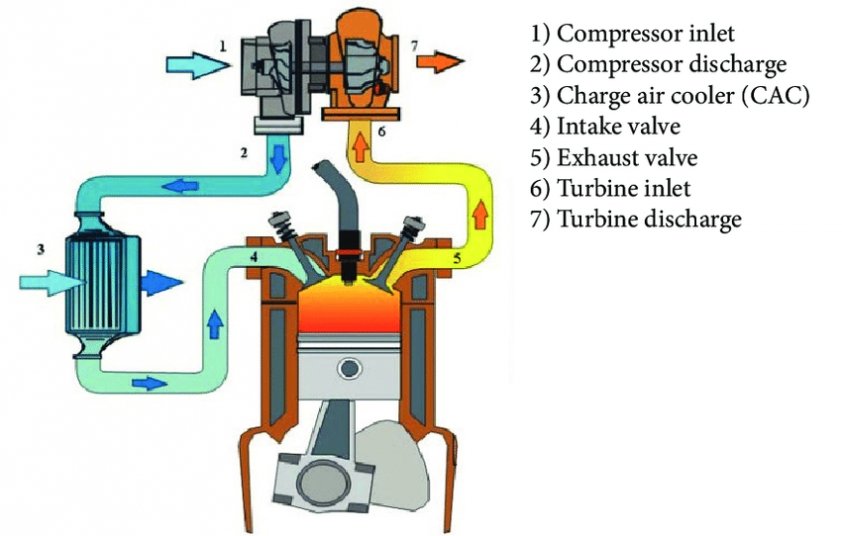

The operating principle of a turbocharger is to optimize the energy source from the exhaust gas to drive the turbine to rotate the engine and pump air into the combustion chamber.

The engine’s exhaust gas is directed to rotate the turbine blade, then rotate the turbo shaft and rotate the blade at the other end, in the opposite mechanism.

The turbo is installed right at the engine’s exhaust port, so to avoid exhaust gas flowing back into the combustion chamber, the system has been equipped with a safety valve system.

Turbo’s operating principle

In fact, there are 3 common types of Turbo:

Single Turbo: This is a single turbocharger, has a traditional structure and is also the most commonly used type of Turbo today.

Single Turbo

Twin-scroll Turbo: Also known as twin-scroll turbocharger, is a type of Turbo equipped for internal combustion engines, but instead of 1 turbine tube, it is equipped with 2 tubes.

Twin-scroll Turbo

Twin-Turbo/Bi-Turbo: Twin turbocharger is a system equipped with 2 traditional Turbo sets at the same time, often used for V6, V8 engines,…

Bi-Turbo

Besides the outstanding advantages compared to conventional engines, Turbo turbocharged engines still have some minor disadvantages.

Advantage:

Increase engine power: To produce the same power, a car equipped with Turbo will only need an engine with a smaller combustion chamber capacity.

Fuel economy: Turbo produces more power than a conventional engine, with the same amount of fuel.

Defect:

Higher cost: Vehicles equipped with Turbo engines will cost significantly more than regular engines.

Hotter engine: Turbo generates a fair amount of heat when processing engine exhaust.

More oil consumption: Turbo has the ability to rotate up to 250,000 rpm, so it will need abundant, continuous oil.

Turbo engine

Below are some notes for vehicles using Turbo engines, helping to ensure safety and maintain the life of the vehicle engine.

1. Limit movement immediately after starting the engine

Because Turbo uses lubricating oil with the engine, at the time of starting the engine, the oil is cool, thick and flows quite slowly.

2. Do not turn off the engine immediately after stopping

For turbocharged engines, you should limit turning off the engine immediately after stopping the vehicle.

3. Pay attention when the car turns a corner

The Turbocharger will have a certain delay when accelerating, easily leading to understeer or oversteer when cornering, leading to the car slipping and losing control.

4. Use gasoline with the correct recommended octane rating

Users should use gasoline with the correct recommended octane rating, otherwise, the vehicle may detonate fuel at the wrong time, affecting the life of the engine and turbocharger.

5. Replace fuel filter on time

The turbocharger rotates with the exhaust gas from the engine, so it is very sensitive to the quality of the exhaust gas.

6. Regularly maintain the intake air cooling system

The Turbo charge air cooling system requires maintenance every 160,000 k or sooner.

7. Check the high pressure gas pipeline system periodically

In many cases, the Turbocharger system fails due to a problem with the high-pressure gas pipeline system, affecting the amount of air entering the engine.

Above is all the information and knowledge about Turbocharged engines, hope the information is useful to you.